Unlock The Secrets Of The Labyrinth Pump: A Comprehensive Guide

Imagine this—you're standing at the edge of a mysterious maze, unsure where it leads but knowing it holds answers to some of life's biggest questions. That's kind of what it feels like when you dive into the world of labyrinth pumps. These aren't just any ordinary pumps; they're engineering marvels with a fascinating history and a ton of practical applications. Whether you're a curious mind or someone looking to solve a specific problem, labyrinth pumps are worth exploring. So, buckle up, because we’re about to take you on a journey through their inner workings, benefits, and more.

Now, let's get real for a second. Labyrinth pumps might sound complicated, but they're not as tricky as they seem. Think of them as the Swiss Army knives of fluid handling. They're versatile, efficient, and can handle a wide range of tasks. From industrial applications to everyday uses, these pumps are everywhere, even if you don’t realize it. So, why are they so popular? Stick around, and we'll break it down for you.

Before we dive deeper, let me ask you something: Have you ever wondered how machines move liquids without getting clogged or overheating? That’s where labyrinth pumps come in. These bad boys are designed to handle tough jobs while staying cool under pressure. And trust me, there's a lot more to them than meets the eye. Ready to uncover the secrets? Let's go.

- Nando Zickgraf The Man Revolutionizing The Tech World

- Geuker Wiedemann The Unsung Legend Of Innovation And Growth

What Exactly Is a Labyrinth Pump?

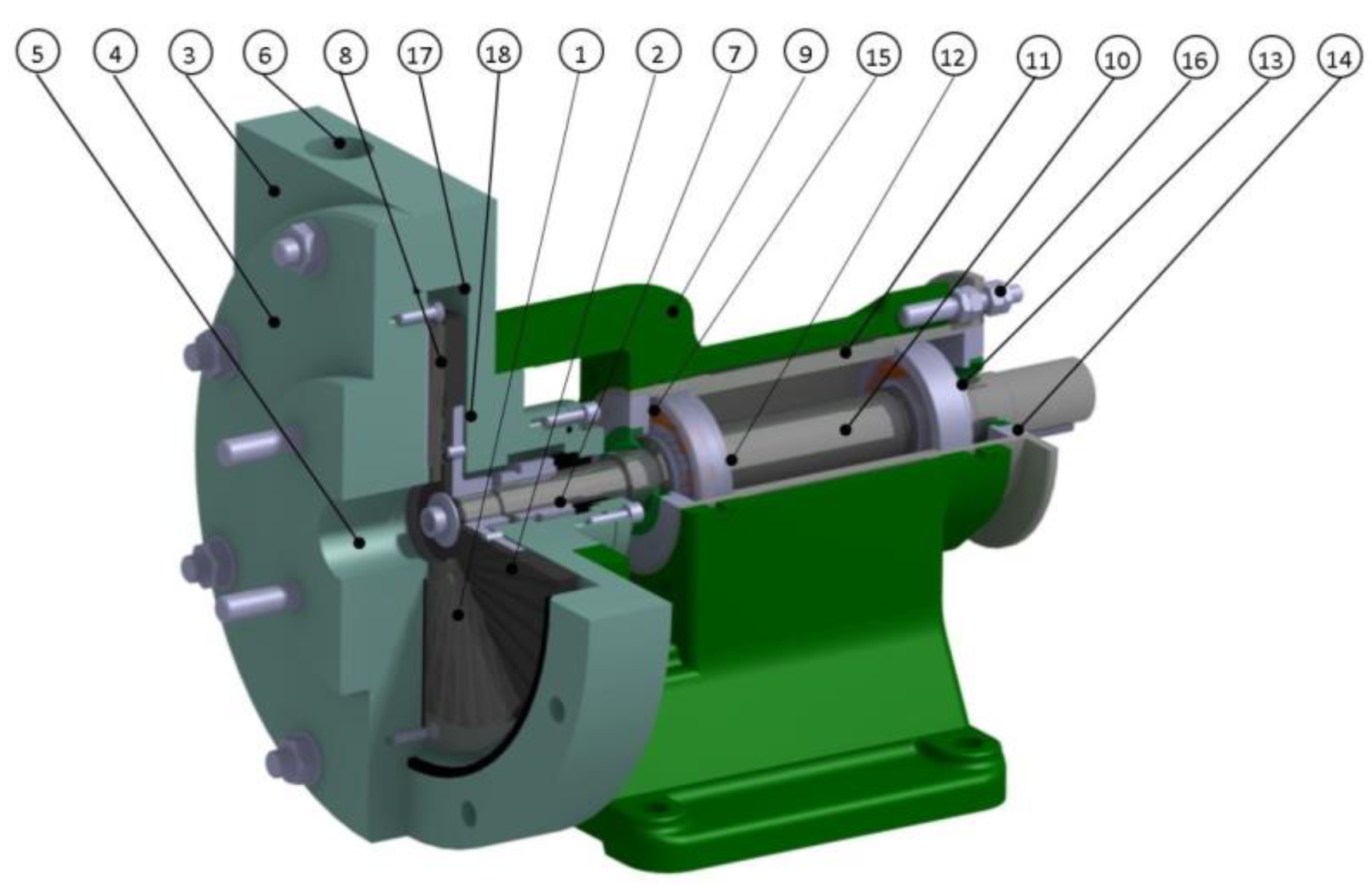

If you're new to the world of fluid mechanics, don't worry. A labyrinth pump is essentially a type of pump that uses a series of grooves or channels to move liquids or gases. Unlike traditional pumps, it doesn’t rely on blades or impellers. Instead, it uses a clever system of seals and gaps to create a smooth flow. This design makes it super efficient and perfect for applications where contamination or wear and tear are major concerns.

Now, here's the kicker: labyrinth pumps are often used in environments where precision and cleanliness are key. Think about medical devices, food processing equipment, or even aerospace technology. These pumps are designed to handle delicate tasks without compromising performance. So, whether you're working with water, oil, or something else entirely, labyrinth pumps have got your back.

Key Features of Labyrinth Pumps

Let’s break down what makes labyrinth pumps so special:

- Dingolfing Weihnachtsmarkt A Magical Christmas Adventure In Bavaria

- Scherrenmuumlhle Oberkochen A Hidden Gem In The Heart Of Swabia

- No moving parts: Unlike other types of pumps, labyrinth pumps don’t have any rotating components. This reduces wear and tear, making them more durable.

- Low maintenance: Since there are no moving parts to replace, maintenance costs are significantly lower.

- High efficiency: The unique design of these pumps allows them to transfer fluids with minimal energy loss.

- Contamination resistance: The labyrinth seal system prevents debris from entering the pump, ensuring smooth operation.

These features make labyrinth pumps a favorite in industries where reliability and performance are critical. But there’s more to the story than just their design. Let’s explore how they work in the next section.

How Does a Labyrinth Pump Work?

Alright, let’s get technical for a moment. The basic principle behind a labyrinth pump is pretty straightforward. It works by creating a pressure differential between two points. Here's how it goes:

Fluid enters the pump through an inlet and flows through a series of grooves or channels. These channels are carefully designed to guide the fluid in a specific direction, creating a smooth flow. As the fluid moves through the labyrinth, it encounters small gaps that help maintain pressure and prevent backflow. This process continues until the fluid exits the pump through the outlet.

What’s cool about this system is that it doesn’t rely on mechanical seals or moving parts. Instead, it uses the natural properties of fluids to achieve its purpose. This makes labyrinth pumps incredibly efficient and reliable, especially in applications where contamination is a concern.

The Science Behind Labyrinth Seals

One of the most important components of a labyrinth pump is the labyrinth seal. These seals are designed to prevent leaks and maintain pressure without the need for physical contact. Here’s how they work:

- Air gap technology: Labyrinth seals use small air gaps to create a barrier between the fluid and the surrounding environment. This prevents contamination and ensures smooth operation.

- Multi-stage design: Most labyrinth seals consist of multiple stages, each contributing to the overall efficiency of the pump. This design allows for greater control over pressure and flow rates.

- Self-cleaning properties: Because there’s no physical contact between the seal and the fluid, labyrinth pumps are less prone to clogging or wear.

These seals are the secret sauce that makes labyrinth pumps so effective. They’re what allow these pumps to handle tough jobs without breaking a sweat.

Applications of Labyrinth Pumps

So, where exactly do you find labyrinth pumps in action? The answer might surprise you. These pumps are used in a wide variety of industries, from healthcare to manufacturing. Here are some of the most common applications:

- Medical devices: Labyrinth pumps are often used in medical equipment like dialysis machines and ventilators. Their ability to handle sensitive fluids without contamination makes them ideal for these applications.

- Food processing: In the food industry, labyrinth pumps are used to move liquids like juices, sauces, and oils. Their hygienic design ensures that food products remain safe and uncontaminated.

- Aerospace: Labyrinth pumps are also used in aircraft engines and fuel systems. Their lightweight design and high efficiency make them perfect for aerospace applications.

- Oil and gas: In the oil and gas industry, labyrinth pumps are used to handle corrosive fluids and high-pressure environments. Their durability and resistance to wear make them a top choice for these tough conditions.

As you can see, labyrinth pumps are incredibly versatile. They’re used in just about every industry you can think of, proving their value time and time again.

Why Choose a Labyrinth Pump?

When it comes to choosing the right pump for your needs, labyrinth pumps offer several advantages:

- Efficiency: Labyrinth pumps are designed to operate with minimal energy loss, making them a cost-effective choice.

- Reliability: With no moving parts to wear out, these pumps are built to last.

- Low maintenance: Because there are no seals or blades to replace, maintenance costs are kept to a minimum.

- Hygienic design: The absence of physical contact between the pump and the fluid makes labyrinth pumps ideal for applications where cleanliness is critical.

These advantages make labyrinth pumps a smart choice for anyone looking for a reliable and efficient solution to their fluid handling needs.

Types of Labyrinth Pumps

Not all labyrinth pumps are created equal. There are several types to choose from, each designed for specific applications. Here’s a breakdown of the most common types:

1. Axial Flow Labyrinth Pumps

Axial flow labyrinth pumps are designed to handle high-volume, low-pressure applications. They’re often used in water treatment plants and irrigation systems. Their simple design and high efficiency make them a popular choice for these types of tasks.

2. Radial Flow Labyrinth Pumps

Radial flow labyrinth pumps, on the other hand, are better suited for high-pressure, low-volume applications. These pumps are commonly used in oil and gas pipelines, where their ability to handle high pressures is crucial.

3. Mixed Flow Labyrinth Pumps

Mixed flow labyrinth pumps combine the best features of axial and radial flow pumps. They’re versatile and can handle a wide range of applications, from industrial processes to household uses.

Choosing the right type of labyrinth pump depends on your specific needs. Whether you’re dealing with water, oil, or something else entirely, there’s a labyrinth pump out there that’s perfect for the job.

Advantages and Disadvantages of Labyrinth Pumps

Like any technology, labyrinth pumps have their pros and cons. Here’s a quick rundown of what you can expect:

Advantages

- High efficiency: Labyrinth pumps are designed to operate with minimal energy loss, making them a cost-effective choice.

- Low maintenance: With no moving parts to wear out, maintenance costs are significantly lower.

- Reliability: These pumps are built to last, ensuring years of trouble-free operation.

- Contamination resistance: The labyrinth seal system prevents debris from entering the pump, maintaining cleanliness.

Disadvantages

- Initial cost: Labyrinth pumps can be more expensive upfront compared to other types of pumps.

- Flow limitations: While they’re great for certain applications, labyrinth pumps may not be suitable for high-flow, low-pressure tasks.

- Design complexity: The intricate design of labyrinth pumps can make them more challenging to install and repair.

Despite these drawbacks, the benefits of labyrinth pumps often outweigh the costs. They’re a smart investment for anyone looking for a reliable and efficient solution to their fluid handling needs.

Choosing the Right Labyrinth Pump

Now that you know the basics, how do you choose the right labyrinth pump for your application? Here are a few things to consider:

- Application: Think about what you’ll be using the pump for. Is it for medical devices, food processing, or something else?

- Flow rate: Determine the required flow rate for your application. Some labyrinth pumps are better suited for high-flow tasks, while others excel at low-flow applications.

- Pressure requirements: Consider the pressure needs of your system. Labyrinth pumps can handle a wide range of pressures, but it’s important to choose one that matches your specific requirements.

- Material compatibility: Make sure the pump is compatible with the fluids you’ll be handling. Some labyrinth pumps are designed for specific types of liquids, so it’s important to choose one that works with your application.

Taking these factors into account will help you choose the right labyrinth pump for your needs. And remember, when in doubt, consult with an expert.

Future of Labyrinth Pumps

As technology continues to evolve, so do labyrinth pumps. Engineers are constantly working to improve their efficiency, durability, and versatility. Here’s a look at what the future might hold:

- Improved materials: New materials are being developed that offer better resistance to wear and tear, making labyrinth pumps even more durable.

- Enhanced designs: Advances in engineering are leading to more efficient and compact designs, making labyrinth pumps easier to install and maintain.

- Increased applications: As industries continue to grow, the demand for labyrinth pumps is expected to rise. This will drive innovation and lead to new and exciting applications.

The future of labyrinth pumps looks bright, and we can’t wait to see what’s in store. These pumps are sure to play a key role in shaping the industries of tomorrow.

Conclusion

There you have it—a comprehensive guide to labyrinth pumps. From their unique design to their wide range of applications, these pumps are a testament to human ingenuity. Whether you’re in the medical field, food processing industry, or aerospace sector, labyrinth pumps offer a reliable and efficient solution to your fluid handling needs.

So, what’s next? If you’re interested in learning more, we encourage you to dive deeper into the world of labyrinth pumps. And don’t forget to share this article with your friends and colleagues. Together, let’s uncover the secrets of this fascinating technology.

Table of Contents

- What Exactly Is a Labyrinth Pump?

- How Does a Labyrinth Pump Work?

- Applications of Labyrinth Pumps

- Types of Labyrinth Pumps

- Advantages and Disadvantages of Labyrinth Pumps

- Choosing the Right Labyrinth Pump

- Future of Labyrinth Pumps

- Conclusion

Detail Author:

- Name : Susanna Schumm

- Username : sydney41

- Email : rwunsch@yahoo.com

- Birthdate : 1997-08-21

- Address : 624 Dejon Fords Suite 921 South Rosalee, LA 72754

- Phone : 505.243.8058

- Company : Mohr, Friesen and Casper

- Job : Landscaping

- Bio : Delectus consequuntur cum quasi corporis maiores unde ullam. Laboriosam tenetur tempore delectus architecto quasi itaque. Nisi aut harum temporibus quasi.

Socials

twitter:

- url : https://twitter.com/hartmannk

- username : hartmannk

- bio : Deserunt itaque consequatur vel recusandae natus alias tempora. Dolor officia sunt reprehenderit. Autem ipsam quis sint voluptatem.

- followers : 4112

- following : 1764

linkedin:

- url : https://linkedin.com/in/hartmann2000

- username : hartmann2000

- bio : Ipsum sit nemo esse deserunt libero nemo.

- followers : 5528

- following : 721

instagram:

- url : https://instagram.com/khartmann

- username : khartmann

- bio : Est optio doloribus dolor necessitatibus perferendis ut deleniti. Ipsam ut qui voluptatem.

- followers : 4447

- following : 549